CCS integration milestone with TotalEnergies

Successful integration of Carbon Capture & Storage prototype

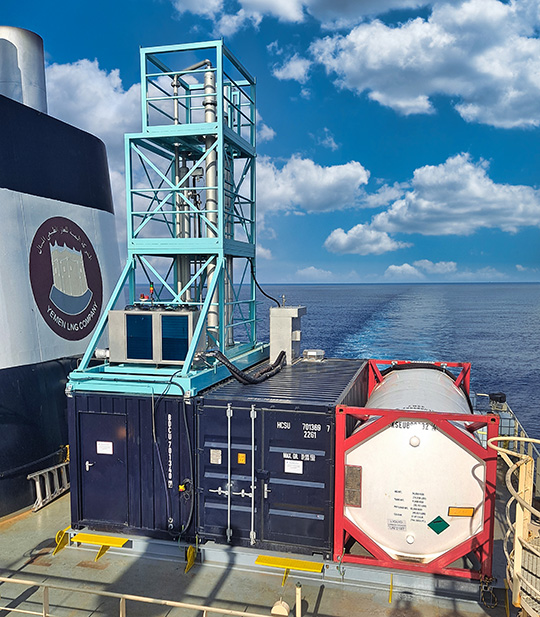

d2m Engineering, in a strategic partnership with TotalEnergies, has successfully integrated a Carbon Capture and Storage (CCS) prototype aboard the SEAPEAK ARWA LNG Carrier. This milestone achievement is part of the EverLoNG project, which aims to advance ship-based carbon capture technology and bring it closer to market readiness.

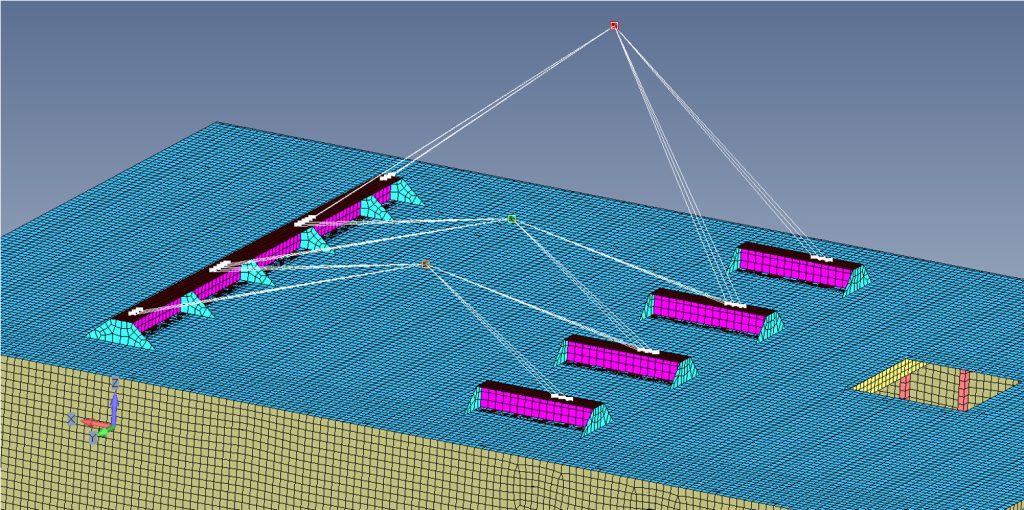

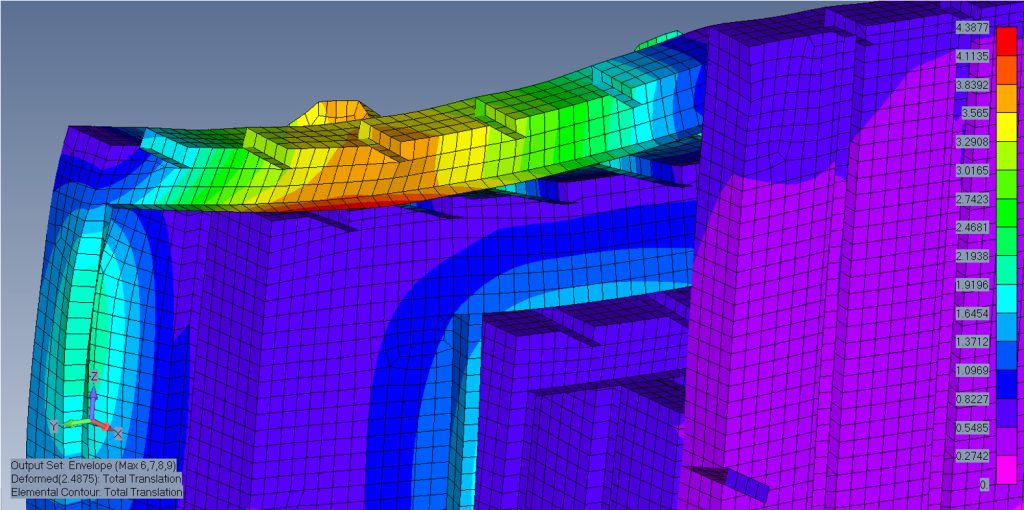

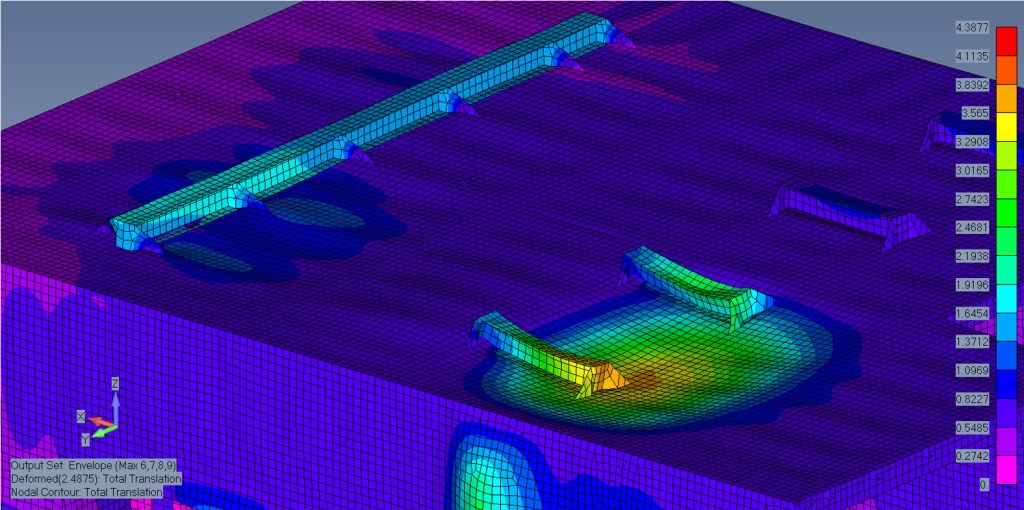

As a crucial player in this innovative endeavor, d2m Engineering conducted a preliminary feasibility study that paved the way for the prototype’s installation. The study included a visit to the sister ship, SEAPEAK MARIB, at Brest port, to determine the optimal location for the prototype. Subsequently, d2m Engineering completed the basic design, including the skid support structure, and generated new diagrams and structural drawings.

Setting sail towards a greener future

The successful installation of the CCS prototype took place during a drydock operation this summer, thanks to the collaborative efforts of d2m Engineering, ship owner Seapeak, and CCS prototype maker Carbotreat.

This achievement underscores d2m Engineering’s commitment to pioneering sustainable solutions in the maritime industry and marks a significant step toward reducing carbon emissions from LNG-fueled ships.

Challenge

The successful integration of the Carbon Capture and Storage (CCS) prototype on the SEAPEAK ARWA LNG Carrier posed an ambitious challenge for d2m Engineering. The primary challenge was to find the optimal onboard location for the prototype, ensuring its effectiveness while minimizing its impact on vessel operations. Additionally, it was essential to execute this integration safely and efficiently during the drydock period.

d2m Expertise

To address this complex challenge, d2m Engineering undertook a comprehensive preliminary study to determine the ideal location for the CCS prototype on board the SEAPEAK ARWA. This study was followed by a visit to the sister ship, the SEAPEAK MARIB, in the port of Brest, to confirm the best position for the installation. Based on the study’s results, d2m Engineering then developed a complete basic design, including a specially designed skid support structure. This solution was implemented during the drydock period, ensuring a safe and successful installation.

Result

The result of this successful collaboration between d2m Engineering, ship owner Seapeak, CCS prototype maker Carbotreat, and TotalEnergies is a significant step toward a more environmentally friendly maritime future. The successful installation of the CCS prototype on the SEAPEAK ARWA LNG Carrier paves the way for a reduction in carbon emissions from LNG-powered ships. It underscores d2m Engineering’s commitment to being at the forefront of sustainable solutions in the maritime industry while demonstrating its ability to tackle the most complex challenges innovatively and effectively.